How Does Our Electrical Rubber Matting Get Made?

If your area of enterprise carefully factors electrical buildings — especially if there are continue to be conductors or the chance of unintended contact — then you are required by means of way of regulation to use insulating Electrical Matting. Should you fail to do so, and one of your personnel is injured or killed due to electrocution, you may additionally be held liable. Our Electrical Safety Mats every insulate closer to electrical shock and furnish ergonomic support, that ability you do now not prefer to sacrifice comfort for the sake of safety. We moreover furnish a range of anti-static mats to aid retain delicate electrical tools safe.

To commence with, we want to set up a vital hold close of rubber. Rubber is a natural dielectric fabric that inhibits the float of electric powered powered price as a quit end result of its molecular structure, stopping the free float of electrons. There are many elements of rubber that make it the high-quality material to use for electrical safety matting. Firstly, rubber is fantastic to act as an insulator (as it is in many functions at some stage in the industry) due to its dielectric and electrically resistant properties. The bendy and cushioning nature of rubber moreover make it the great cloth to use for electrical rubber matting.

Electrical protection matting requires strict extraordinary manipulate strategies as any factors (dyes, fillers, preservatives and curatives) that can also additionally have been introduced to the rubber can have an effect on the electrical resistance of the rubber and therefore how it performs under a vary of circumstances. It is for this purpose that our electrical rubber matting is vigorously tested.

How do we produce our Electrical Rubber Matting?

At Martin’s Rubber, we comply with a manner that via no potential fails to grant the best rubber mat for electrical safety. This manner consists of four phases, including:

Mixing: The manner of manufacturing Electrical Rubber Matting starts of evolved with mixing. The factors are exactly weighted in accordance to the formula. Following this we pre-heat the mix between 95°C and 104°C and then, we wholly mix and use a roller to solid off any trapped air to produce an unvulcanised sheet spherical 2mm-3mm thicker than the carried out requirement.

Calendaring: The compound of the mixture is then flattened. Due to the pre-heating treatment previously on, we can make positive a normal operation of the calendar and minimal shrinkage. The roller ground temperature is managed to +/- 1°C.

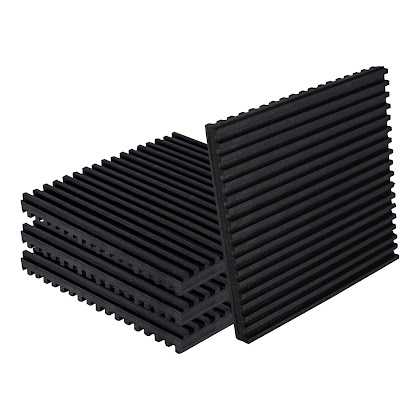

Retouring: The 2nd section of the calendaring method is carried out on retours, the region a ribbed pattern is utilized to the pinnacle ground and figuring out tape is utilized to the underside.

Drying & Testing: We then air-dry the rolls until now than passing them by means of a 2-electrode making an attempt out station. This ensures that every going for walks meter complies to the proper electrical specification in accordance to the thickness; 11kv at 6mm and 15kv at 9.5mm.

Finishing: After having discovered the system described above, the material is then wound into rolls and is made reachable to you in each a full roll or limit down to a special size. electrical safety mats are necessary parts of defensive tools that furnish you with protection from immoderate voltages. Electrical Safety Mats need to comply with licensed enterprise standards, making positive your protection. Electrical protection mats are moreover acknowledged inner the corporation as electrical insulation mats and switchboard matting.

.jpg)

Comments

Post a Comment