How Do We Produce Our Electrical Rubber Matting?

Insulating matting additionally recognized as dielectric or electrical security matting is used to shield human beings and components of electrical tools used in swap rooms, in the front of switchboards, transformers and different excessive voltage workplaces. Electrical has a international popularity for excessive fine matting. Our matting is used globally via clients who are stay working and by means of electrical engineers in areas such as Power Utility, Petrochemical, Marine, Data Centers, Banking and Engineering. Electrical has provided a large vary of top notch Electrical Safe Matting regularly referred to as switchboard matting. Rubber is regarded for its excellent electrical insulating properties. With the potential to limit or quit electric powered currents, electrical rubber matting or switchboard matting is a frequent floor for high voltage environments.

To begin with, we should set up a simple grasp of rubber. Rubber is a herbal dielectric cloth that inhibits the go with the flow of electric powered cost as a end result of its molecular structure, stopping the free float of electrons. There are many factors of rubber that make it the best cloth to use for electrical security matting. Firstly, rubber is appropriate to act as an insulator (as it is in many functions at some stage in the industry) due to its dielectric and electrically resistant properties. The bendy and cushioning nature of rubber additionally make it the ideal fabric to use for electrical rubber matting.

Electrical protection matting requires strict best manipulate techniques as any components (dyes, fillers, preservatives and curatives) that may additionally have been introduced to the rubber can have an effect on the electrical resistance of the rubber and consequently how it performs underneath quite a number circumstances. It is for this motive that our electrical rubber matting is vigorously tested.

How do we produce our Electrical Rubber Matting?

At Martin’s Rubber, we observe a manner that by no means fails to supply the best rubber mat for electrical safety. This manner consists of 4 phases, including:

Mixing: The procedure of manufacturing Electrical Rubber Matting starts of evolved with mixing. The elements are precisely weighted in accordance to the formula. Following this we pre-heat the combine between 95°C and 104°C and then, we wholly combine and use a curler to cast off any trapped air to produce an unvulcanised sheet round 2mm-3mm thicker than the completed requirement.

Calendaring: The compound of the combination is then flattened. Due to the pre-heating remedy formerly on, we can make certain a regular operation of the calendar and minimal shrinkage. The curler floor temperature is managed to +/- 1°C.

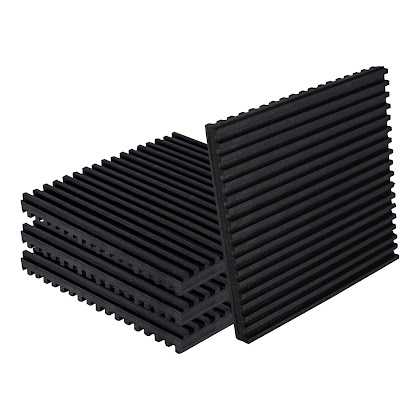

Retouring: The 2d phase of the calendaring technique is carried out on retours, the place a ribbed sample is utilized to the pinnacle floor and figuring out tape is utilized to the underside.

Drying & Testing: We then air-dry the rolls earlier than passing them via a 2-electrode trying out station. This ensures that each strolling meter complies to the right electrical specification in accordance to the thickness; 11kv at 6mm and 15kv at 9.5mm.

Finishing: After having accompanied the system described above, the fabric is then wound into rolls and is made handy to you in both a full roll or reduce down to a particular size. electrical security mats are necessary portions of shielding gear that supply you with safety from excessive voltages.

.jpg)

Comments

Post a Comment